Switch to Gantry 5

Posted on

6th Nov 2025

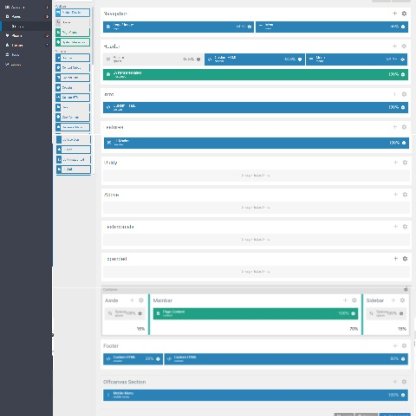

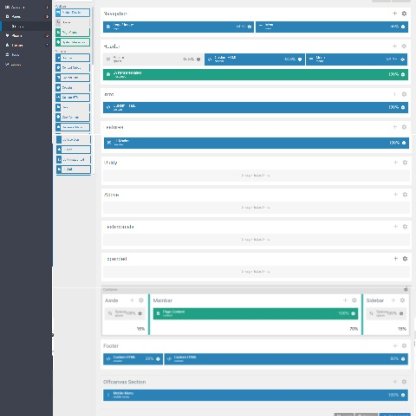

In my conversion of a website for a club in my community, I stumbled across Gantry 5. 5.5 had just been released a couple days earlier.

While Gantry has been around for at least 4-5 years, it was something I was not acquainted with.

Web Design

Posted on

3rd Oct 2025

Web design services

Coridium LLC has been designing and maintaining web sites for 20 years, starting with our own. The first designs started with simple html pages edited by hand, then moving onto blocks, and now we use a CMS (content management system) based on Grav. Grav is an easy to use open source flat-file CMS. It has many themes to provide different web page layouts. Once setup, we ca...

Some more gripes about Win11

Posted on

29th May 2025

While I have been using Win11 for a month of so now, basically it is OK. But there are a couple issues I have run into, that is in helping others in my neighborhood keep there PCs running.

Late to the Win11 party

Posted on

9th Apr 2025

As the end of Win10 gets closer, I finally bit the bullet and got a new Win11 PC. Part of the fact was that I seem to be the IT guy for our community, which is great. And I was running into a lot of people with new Win11 machines with a number of really weird problems caused by Win11. So I was hesitant to switch.

So how to move my old system over (lots of programs and files and settings and ...)

Nearly lost the recipe

Posted on

9th Feb 2025

Checking out a new batch of ARM Stamps, I plugged a new one in and all that I saw was unknown USB device.

Back to hardware design

Posted on

16th Jul 2024

It was time to build some more boards for our OEM customers.