The SuperPRO is footprint and pin compatible with the Arduino PRO. In

addition it has an onboard 5V regulator so it is compatible with 5V shield

boards. The SuperPRO also has an RTC crystal and provision for a battery.

The PROplus has only a 3.3V power supply and does not include the RTC

crystal. Both boards can be used with 5V TTL signals.

BASIC or C programs can be downloaded using the installed test connector

using the USB dongle contained in Coridium's evaluation kit or using the SparkFun USB Basic Breakout board or FTDI cable from Digikey. More details on these

connections here.

Digital IO connections -- rev 5

or later

The rev 5 adds a parallel connection for pins

that are on 0.1" centers. This artwork is also shared with the

PROplus version of the board.

The SuperPRO uses an LPC1756 and has 5V and 3.3V

supplies.

The simpler PROplus uses an LPC1751 and has only

the 3.3V supply.

Port pins can be controlled with the

P0..P4 keywords . and with firmware 8.12 or

later the original

IO, IN, OUT.. keywords

. More details on the GPIOs can be found in the NXP User Manual.

Below is a diagram of the pins, note it has been

rotated 90 degrees to make it easier to read,

All boards rev 5 and later share the SAME

pinouts, except for the location of the load-C jumper. To use IO(x) with x

greater than 32, firmware 8.11 or later has to be used. IO(32) is the

equivalent of P1(0) and can be accessed either way in the latest firmware, in

earlier versions P1(0) was the way to access that pin.

Special purpose pins

RESET pin starts the ARM program if the

BOOT(P2.10) pin is high. If you use P2.10 as an input you MUST make sure

it is in the high state when RESET is asserted, otherwise your program will NOT

start.

The LPC1756 supports a number of dedicated functions.

Those include 4 UARTs, USB, 2 SSPs, 1 SPI, 2 CAN, 2 I2C, I2S, 2

multi-channel PWMs, Quadrature Encoder, dedicated motor control PWM, interrupts,

timer counter capture and match.

In addition most can be configured with pull-ups and default to

pull-ups following reset.

Details can be found in NXP's User manual.

UARTs are enabled by calling BAUD(x) for x=0 to 3. UART0

is enabled by default as the programming debug connection. The pin

assignment BASIC uses is in the following table (you can change the settings by

changing the PINSEL registers, details in the NXP User Manual)

| UART |

BASIC |

NXP |

UART |

| RXD(0) |

IO(3) |

P0(3) / AD(6) |

UART0 |

| TXD(0) |

IO(2) |

P0(2) / AD(7) |

|

| RXD(1) |

IO(65) |

P2(1) |

UART1 |

| TXD(1) |

IO(64) |

P2(0) |

|

| RXD(2) |

IO(73) |

P2(9) |

UART2 |

| TXD(2) |

IO(72) |

P2(8) |

|

| RXD(3) |

IO(157) |

P4(29) |

UART3 |

| TXD(3) |

IO(156) |

P4(28) |

|

Analog connections

4 A/D converters are readily available, Analog

2-4. 2 more are available, but share the pins with UART0 -- what was NXP

thinking, I have no idea.

1 10 bit DAC is available shared with AD(3)

available on the SuperPRO (not on PROplus)

On reset or power up the AD pins are configured

by software as AD inputs. To change those to digital IOs, the user

must write to the appropriate PINSEL register, or with version 8.11 firmware or

later you can change it to an IO by accessing the corresponding IO pin in the

following table.

| AD |

BASIC |

NXP |

| AD(2) |

IO(25) |

P0(25),DACOUT |

| AD(3) |

IO(26) |

P0(26) |

| AD(4) |

IO(62) |

P1(30) |

| AD(5) |

IO(63) |

P1(31) |

| AD(6) |

IO(3) |

RXD(0)/P0(3) / AD(6) |

| AD(7) |

IO(2) |

TXD(0)/P0(2) / AD(7) |

The LPC1756 does support an external

reference for the A/D converters, but to use the Arduino AREF pin a jumper

is required (details on the schematic)

The A/D input requires a drive impedance of 7.5K

or less (see NXP LPC175x spec sheet). We've also found a 100 to 1000 pF

cap from AD input to GND can remove high frequency noise affecting high order

bits in the converter.

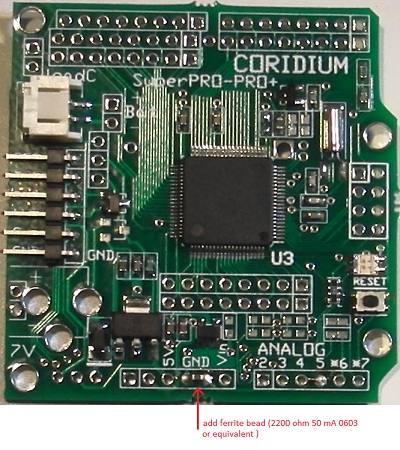

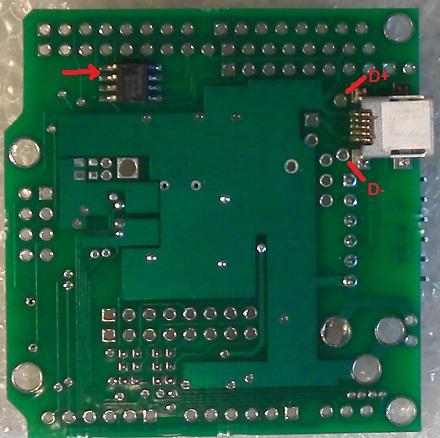

Analog Isolation

The rev 6 and 7 boards isolate both GND and power

for the analog section using ferrite beads.

to add isolation to rev 4/5 boards

-

The LPC17xx series chips AD converter are

sensitive to high frequency noise on the analog GND (Vssa) or on the AD inputs

themselves. A symptom that will show up is bits in any bit position turned

on/off when the conversion is done. This makes it hard to average out, but

conversion can be voted on, choosing 2/3 conversions that agree within a few

bits. The occurrence of these errors is in less than 1% of the conversions,

unless your setup is very noisy.

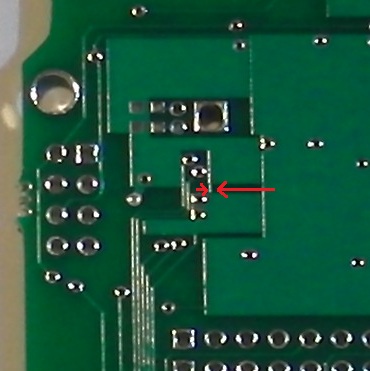

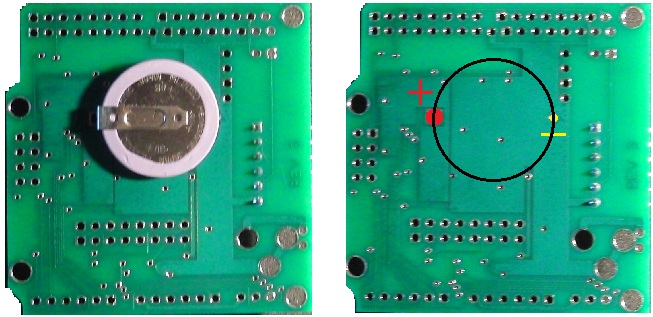

Another option is to change the analog GND

connection on the board. Do this by cutting the trace on the back side

between GND under the crystal and the GND connected to Vssa (shown on the

picture below)

Then connect digital GND to analog GND using a

ferrite bead, a convenient place to do this is on the front side as shown

below.

Pin limitations

P0.29 and P0.30 direction control must be done in

parallel, they can be both outputs or both inputs, but not mixed. With

firmware 8.11 or later, changing the direction of either P0.29 or P0.30 will

change the other pin.

Power connections --

SuperPRO

Pads for a Cui PJ-002A or

SparkFun

PRT-119 power connector are available in the lower left hand

corner.

For both battery and 6V input, 2 pin 0.1" spaced

holes are available for wires or headers. When using the battery

connector, total current draw for the board must be limited to 200mA. If

you want to use more current, you should install a jumper around the D2 diode

(holes are available above D2).

Diode steering allows power to be supplied from a barrel

connector from a 6V unregulated source, 5V USB test connector, or the battery

connector. Because of the Schottky diodes, all 3 power sources can be

connected simultaneously. If you are using an

unregulated wall transformer, you must check the open circuit voltage and it

MUST be less than 12V.

When the 6V source is used, 5V Arduino shields can be powered

from the SuperPRO.

The schematic below describes this circuit on the SuperPRO

Power connections --

PROplus

Pads for a Cui PJ-002A or

SparkFun

PRT-119 power connector are available in the lower left hand

corner.

For both battery and 6V input, 2 pin 0.1" spaced

holes are available for wires or headers. When using the battery

connector, total current draw for the board must be limited to 200mA. If

you want to use more current, you should install a jumper around the D2 diode

(holes are available above D2).

Diode steering allows power to be supplied from a barrel

connector from a 6V unregulated source, 5V USB test connector, 5V from a shield

or the battery connector. Because of the Schottky diodes, all 3 power

sources can be connected simultaneously. If you are

using an unregulated wall transformer, you must check the open circuit voltage

and it MUST be less than 12V.

The PROplus only has the 3.3V regulator, so it cannot supply

power to a 5V shields.

The schematic below describes this circuit on the PROplus

Power connections details

The 3.3V regulator can supply 50 mA, with most

being used by the LPC2103. The 3.3V connection next to RESn on the lower

power connector is only connected if the shorting pads are shorted (NOT the

factory default).

The analog GND should be used to connect to the

GND of analog inputs. Digital and Analog GNDs are connected together with

a small trace, but to minimize noise you should use the analog GND only for

analog signals.

Jumpers and test connector for Program

Download

The USB Dongle from Coridium will supply 5V from the USB to

power the ARMmite PRO. It also controls the RESET and BOOT(P2.10) signals to

automatically load C or BASIC programs using MakeItC or BASICtools.

Remember, if you load a C program, it will erase the BASIC firmware and you will

not be able to load BASIC programs after that.

When using the SparkFun FTDI Basic Breakout Board, a limited

amount of power can be supplied from the BBB, but this is limited to 50 mA and

after diode drops, its about 2.8V to the LPC2103. In practice this will

run, but it is outside the part specifications, so it should be

limited in use.

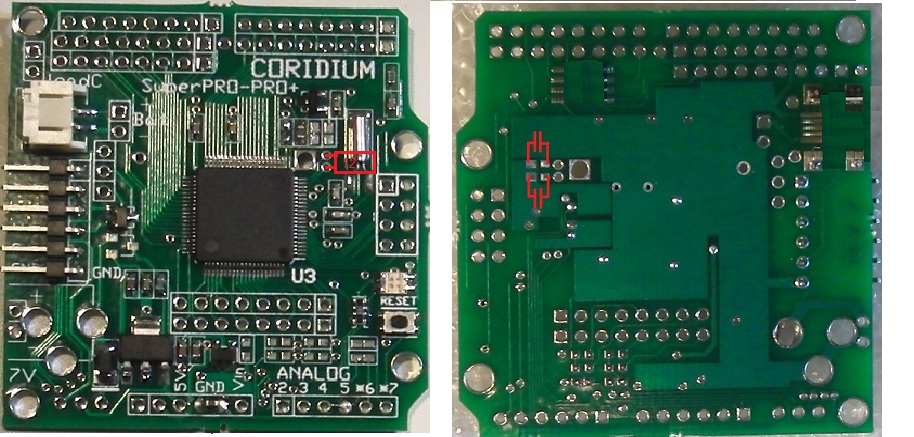

Also with the SparkFun FTDI Basic Breakout Board to load a

C program, the LOAD C jumper needs to be installed, then removed to run the

program. BASIC programs can be loaded and controlled using the SparkFun

board, with no additional steps/jumpers.

PROplus

SuperPRO

An alternative is to use a 2 pin header with a shorting block

(pictured below)

Real Time Clock Oscillator

The RTC oscillator of the LPC17xx

parts has been resolved. The first generation

parts which were shipped in early 2011 had an unreliable oscillator and this has

been corrected by NXP.

A 32 KHz crystal and diode for battery backup with an optional

ML2020 rechargeable Li battery.

A Panasonic ML2020H rechargeable battery may be added to keep

the real time clock running when power is removed. The battery is mounted

on the back of the board as shown below. The VL2020/HFN will also work,

though it is more expensive and has less power.

USB connector option for power and SPI Flash

option

The rev 6/7 boards add pads for an optional

SPI Serial Flash (note pin 1 location). Also pads for a USB mini-B

connector have been added, this is intended primarily to supply power, and the

data lines are connected to pads. These options can be installed at

Coridium for orders of 10 boards or more. Contact

sales@coridium.us for

details.

Main Clock Crystal

option

You can add a

12 MHz crystal with 39pf 0603 load caps, for use as a more

accurate clock source. Locations marked below