by Zeke

Wow, what a week! Started this blog report with the goal of making a 'Dice' roller for my war-gaming. I had some TIL-311 dotmatrix hexadecimal displays from way back when. [old]

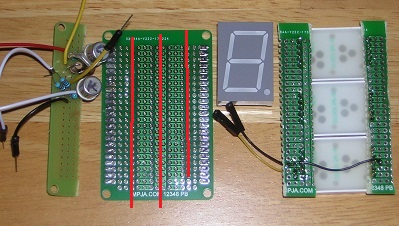

Grabbed an old RadioShack memory board. Talk about memories!

(pun intended!) I was going to expand a CoCo Computer II.

This pcb was made for the 3 voltage(!) dynamic RAM memory chips

from the 80's. +5,+12,-5 and they had to be sequenced

That is why you see three buss strips on one

edge - ground is on the other. I had to cut some of the

interconnects to isolate the individual display chip-select

lines. This is my board and picture!!(ie. not stolen/borrowed)

So, now we need to figure out how much power these guys use.

There went about an hour on the internet looking for datasheets

and checking them. I was hoping to give us a link to a 4 or 6

digit display assembly, but

mpja nor

adafruit have any.

Mpja has the single/double LED displays.

allelectronics

has a

SparkFun

4-DIGIT 7-SEGMENT SERIAL DISPLAY - using an arduino to control

it via a serial-type interface. Man, things have changed. [new]

USB is serial, SPI is serial, harddrives use SATA [Serial ATA]

Power, how much power will I need? Mixing the newer 3.3v and

the older 5v logic is a gamble. The ARMstamp is 5v tolerant,

meaning you can connect 1 (possibly 2)TTL load to it. These

lower voltage devices are meant to connect with other low voltage

chips - which implies a buffer/driver chip for TTL!

A TTL load is about 1.6 ma, and the ARMstamp has a 4 ma limit

per pin [as do most all other modern microcontrollers- AFAIK].

Some Atmel parts - like the Arduino series were built with 10-20ma

pins - so as to drive LEDs and such !!

Power Sequencing is another issue. The external components

cannot/should not be energized before the microcontroller is up;

otherwise the external components are supplying power to the microcontroller

through the I/O pins ! (which aren't configured properly for the connected

devices).

Well - so I am about ready to solder the displays down, when the thought comes to mind -'Test 'em first!'. Glad I did, 'cuz all of them were defective!! I had been babying these for about 20 years, and now they are dead. Possibly static electricity - it can get up to 800-1000volts - no current to speak of; but the discharge is deadly to chips - the low voltage ones even more so. (wear static discharge wrist straps)

Now what do we do? Well, I had ordered some of the 1" LEDs from mpja.com and they just arrived. They need at least 2.2vdc and 10-15ma per segment!! So turning on all 7 segments could be more than 100ma; and a USB port is spec'd at 500ma. That will be my next phase - get them buffered and powered.

I now have an added incentive -- exercise timer! I plan on using a pot on one of the analog inputs to create various "modes of operation"; one input with multiple choices via the ARMbasic programming software -CASE/SELECT structure. Switches would require an input for each choice, being that digital is a '1' or a '0' [on or off].

Time to get to work -- see ya' later, alligator ! (a youthful parting phrase)

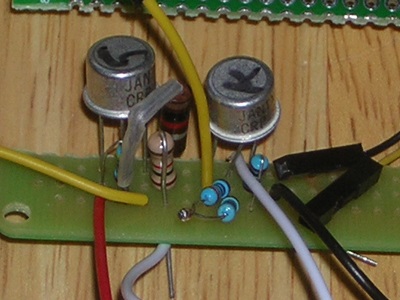

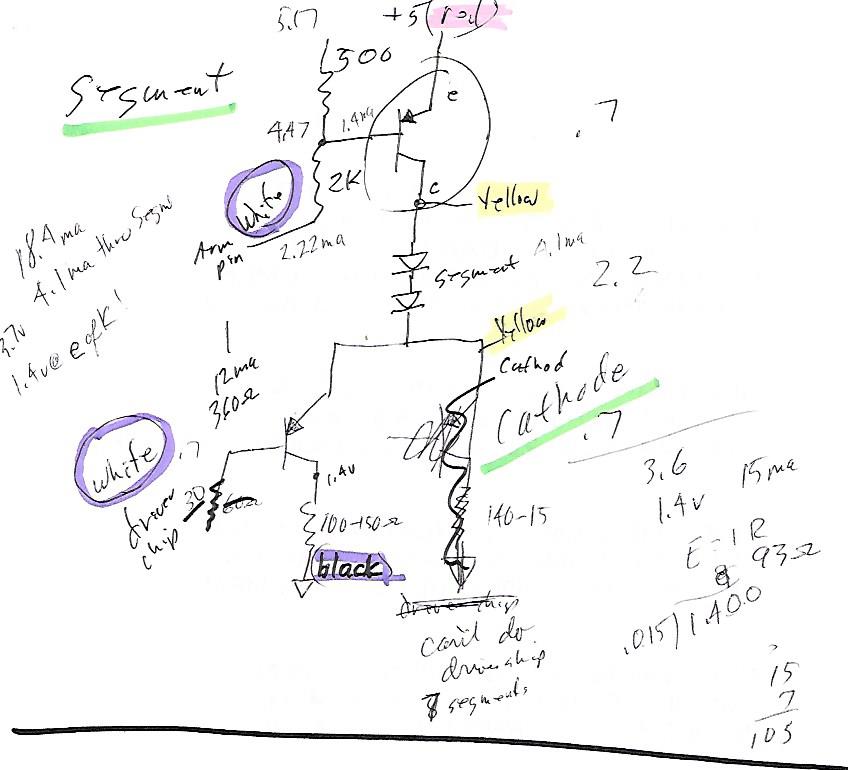

Post Script 13 Jan Now I know why TTL chips were made! I couldn't find any appropriate driver/buffers (4511 for common cathode BCD coded; 7446 for common anode BCD coded) so used what I had on hand - a bunch of 2N2905 PNP transistors. I decided to wire/solder up a single segment setup - one '05 for the segment enable - one '05 for the cathode enable [basically a chip enable]. The cathode ('K' in the picture) needs to handle current for 7 segments; 10ma per segment is good (20ma is max) so that is 70+ ma per LED chip - more than any pin can handle - even for the Arduino chips!. The base(b) current controls how much current flows through the transistor; and in the case of PNP it has to be more negative than the emitter(e).

Several hours later, several readjustments to my resistors and I have a ONE segment, one chip LED driver.

I started out by cutting the proto board into 4 long pieces so I could mount the LEDs. They weren't on true .1" centers. Had the two outer strips available so I put the components on it.

I will show you my basic worksheet - 3rd one; only because I am going another route!

I am going to order driver ships - we'll need one for each of the 6 LEDs, and other parts.